Piston Lathes

DOWN THE YEARS

Throughout the overall piston manufacturing process, the turning of the skirt’s convex and oval profile has achieved an outstanding level: it is a complex machining process with 4 controlled axis and millesimal tolerances.

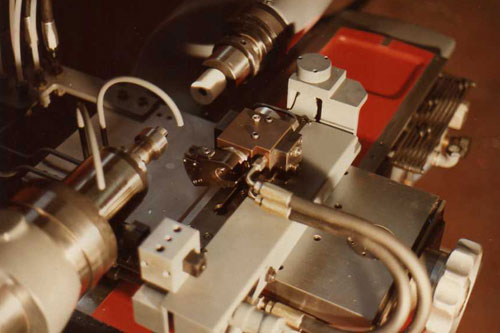

The expertise for such a complex machine comes from the very beginning of the company’s activities, when diamond turning machines were produced mechanically copying a master piston cam. Subsequently all the other technological advancements were developed (piezoelectric system, magnetic wave system, servo valve system, etc).

NOWADAYS

The evolution of the lathe for complex profiles has been greatly influenced by the new technologies that emerged in the early 1990s:

- Electronic data processing systems operating in microseconds, faster than conventional numerical controls;

- Ovality (non-round) generation systems with frequencies response over 150 Hz;

- High-precision control devices (feedback), with millesimal accuracy;

Further advanced applications (like: electrospindle with digital encoder, optical liners on working axes, digital engines, control transducers, micrometric positioning) have turned the piston lathe into a special machine capable of reaching oscillation values of 1 mm (and beyond) at speed over 3,000 rpm, with an accuracy of the tool’s dynamic positioning within +/- 2 microns.

Operator interfaces have also been significantly improved thanks to a proprietary software that can generate complex sinusoidal profile’s charts for the ovality in combination with longitudinal profile programming.

Therefore, the final piston machine setup (as with any irregularly shaped part) is determined by the the syncronization of the convex profile (X and Z axis interpolation) and ovality (O and C axis synchronization). This unique setup makes it possible to divide their respective values into two charts with a 5 degrees programming for the charts with a 5 degrees programming for the polar section and 100 points programming for the longitudinal section.

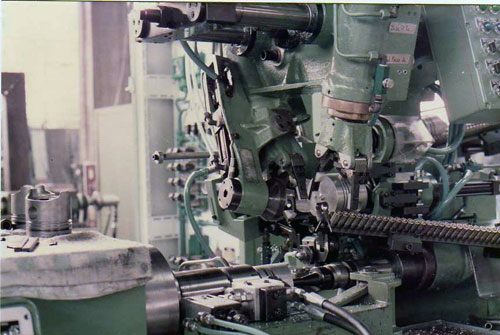

Thus, modern lathes piston appear as machine tools such as horizontal lathes or 1 or 2 spindles vertical milling/turning units with and 1 or 2 tool-holder turrets.

Recently, we have built several machines for the complete machining of the piston’s external skirt, both for longitudinal profiles and ovality generation.